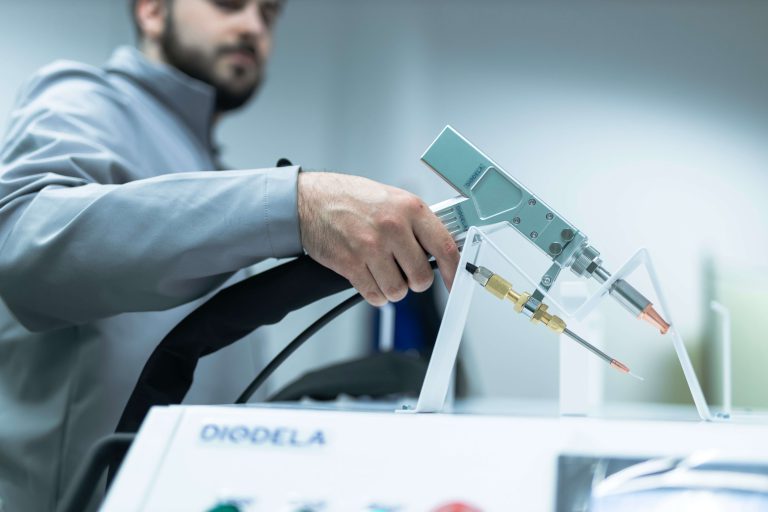

Diodela is a Photonics solutions provider for Industry. Diodela was originally founded as a spin-off from the Center for Physical Sciences and Technology (FTMC). Using FTMC developed and exclusively licensed laser technology our company produces Industrial laser systems for laser welding, cleaning, and other photonics-based material processing. Due to close collaboration with laser science centers and vast experience in photonics, the Diodela team is able to build innovative and precise laser machines that meet all Industrial needs.

At Diodela we use laser technology to create a better experience of welding and material surface cleaning with unlimited precision, high efficiency, and no thermal distortion. Our laser systems are made by professional scientists and engineers using the best theoretical and practical experience. We closely cooperate with Industrial companies to understand their needs and offer a solution that improves their technological processes. We maintain full control of production processes, ensure high quality, competitive prices, fast production times, and professional customer support.

At Diodela our laser systems are built to increase our customers’ productivity and earnings, at the same time being user and environment–friendly. Our mission is to create an industrial breakthrough by supporting innovative companies with excellent quality and client-orientated photonics solutions.

We encourage industrial companies to innovate and be many steps ahead in their industries. Diodela will make this journey smooth, cost, and time effective.